In addition to facing harsh weather conditions, solar plant components must also endure other challenges.…

UV stability of HellermannTyton Products tested by Fraunhofer ISE

A crucial factor in choosing the correct fastening and fixing components for cable installations is that they are manufactured from materials that meet the individual demands and specifications of the intended application.

This is especially true of solar applications, where the effects of weathering, such as ultraviolet radiation (UV), rule out the use of many conventional materials.

HellermannTyton recently commissioned Germany’s Fraunhofer Institute for Solar Energy Systems ISE to perform an extended weathering test on its range of UV-stabilised cable ties according to subsection 10.10 (Pre-Aging) of the IEC 61215 standard (Crystalline silicon terrestrial photovoltaic (PV) modules).

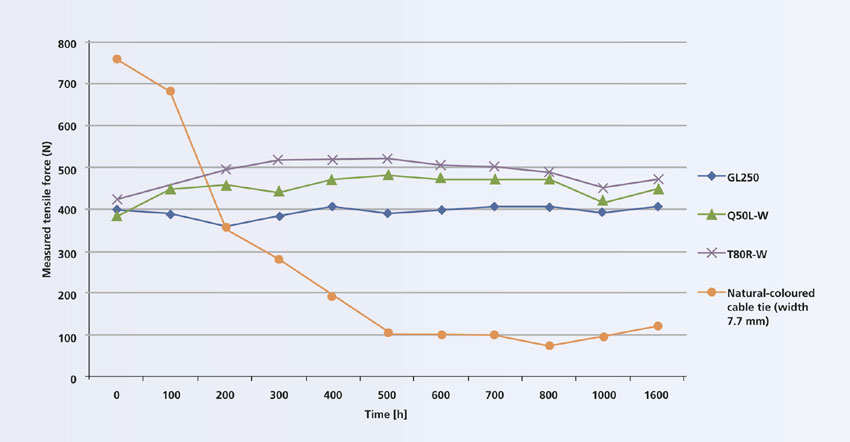

The HellermannTyton products tested by Fraunhofer ISE were UV-stabilised cable ties from the GalvaLok Series (GL250), the T-Series (T80R-W) and the Q-Series (Q50L-W). All three objects were tested alongside a natural-coloured, conventional polyamide 6.6 (PA66) cable tie to compare their respective performance.

Update: in 2017 in Europe we changed the name from GalvaLok to the PA11 series. The GalvaLok brand name is widely known in Asia and has been retained there for our cable ties made from polyamide 11.

GalvaLok ties are made of high-performance polyamide 11 (PA11), which is derived from sustainable castor oil sources. PA11 is proven to be extremely stable when exposed to UVradiation.

The T-Series and the Q-Series ties tested are made from UV-stabilised PA66 and are also suitable for a wide range of cable bundling and tying applications.

The four cable ties of different materials were fastened under load to test cylinders and then exposed to UV radiation at controlled intervals inside a test chamber. Thereafter, the ties were subjected to a loop strength test performed according to section 9.5.1 of the VDE Institute’s DIN EN 62275:2010.07.

The specimens spent up to 1,600 hours in the test chamber and were exposed to a UV dose of 156.78 kWh/m2. This amount of artificial irradiation complies with the assumption that Central Europe is exposed to natural solar irradiation of 1,000 kWh/m2 per year, with about 5% of this being in the damaging UV range. The test corresponded to approximately 3 years of outdoor exposure. Since the intensity and coherence of UV irradiation in the test chamber are not met under natural conditions, these values will be compared to the results of an on-going comparative outdoor exposure over 3 years in Freiburg, Germany and the Negev Desert in southern Israel.

The results of the tests at Fraunhofer ISE document the average values of the loop pull test under artificial weathering conditions as follows:

- The natural-coloured standard cable tie (7.7mm width) manufactured from PA66 showed clear signs of damage due to the effects of UV light after just 200 hours. The loop holding force sank to below half the initial value.

- In contrast, the Q50L-W (Q-Series) and T80R-W (T-Series) ties manufactured from UV-stabilised PA66 and the GL250 (Galvalok) from PA 11, showed almost no effects of UV weathering within the timeframe of the experiment.

The Fraunhofer ISE test on HellermannTyton cable ties was conducted under artificial conditions inside a chamber. In order to compare the results of the simulated test with real life scenarios over a longer period of time, the same ties are currently undergoing three years of natural weathering tests in Freiburg, Germany and the Negev Desert in southern Israel.

#901