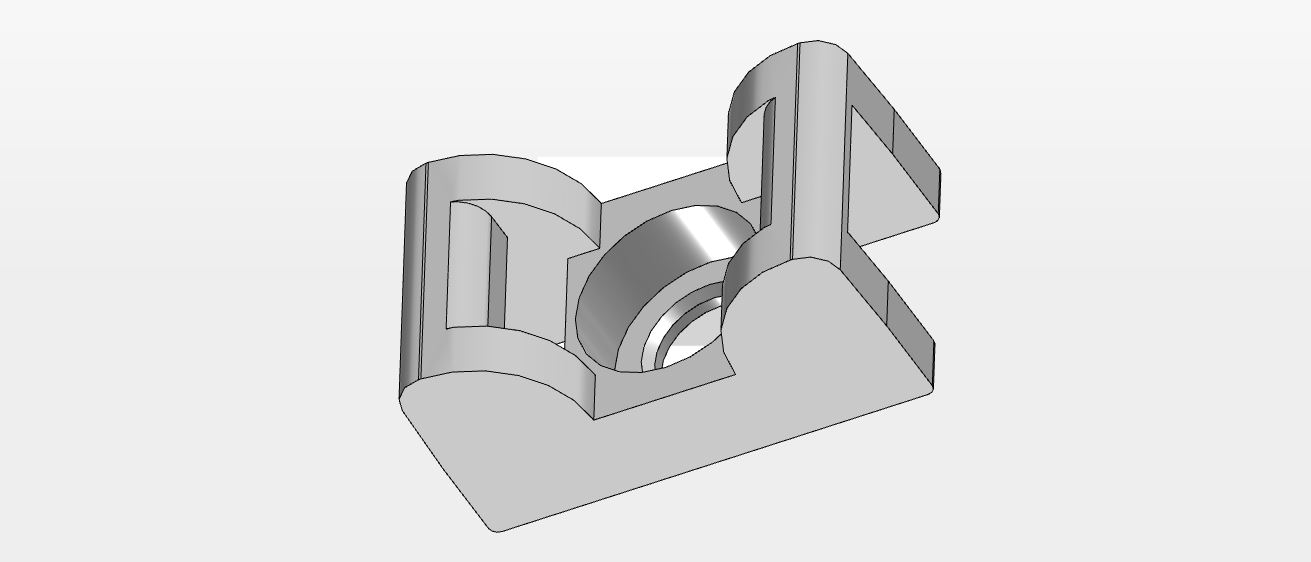

Obtaining the right components more effectively by means of CAD data

To survive in international competition, manufacturers strive to keep the cost of production as low as possible. Yet even though suitable parts might be available on the market at a cheaper price, many still produce components more expensively themselves. By providing CAD data and 3D previews online for free, HellermannTyton now gives engineers an easy means of finding the right solution for their construction needs. … Continue reading