It is hard to imagine a world without hydraulic technology. Fluid power, or hydraulics (Greek…

How to provide extra protection and insulation to cables with hotmelt adhesive

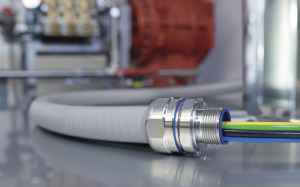

When cables or connectors need extra protection and insulation, such as when installed outdoors or even buried, the best option is to use heat shrink tubing with inner adhesive. This will guarantee, thanks to its high adherence, an extremely efficient seal, preventing the entrance of dirt and humidity in both outdoor and indoor environments – even if buried underground without additional protection.

The hot melt adhesive is usually an ethylene vinyl acetate or thermoplastic polyester elastomer adhesive that is heat-activated using a hot air gun. The type of hot melt adhesive varies depending on the type of application and the application temperatures. In terms of viscosity, the application is very similar to that of heatshrink tubes without adhesive, but tubings with inner adhesive provide an additional protective layer with better adhesion.

Step-by-Step application

Before applying the thin, medium or thick wall heat shrink tubing with inner adhesive it is necessary to roughen your cable in order to get more surface. Then clean it to remove any dirt or grease. When the tube, cap or mold has no hotmelt adhesive inside, it is necessary to slightly roughen the inner wall as well, this will ensure even better adhesion.

Barry and Mark, HellermannTyton heatshrink experts, demonstrate in the video below in a very practical way how this cleaning should be done.

After roughening and cleaning, place the heat shrink tubing with inner adhesive on the surface to be insulated and heat it with the hot air gun from the centre to the ends. This will ensure contraction as well as melting and bonding of the adhesive. For heat shrinkable tubing without an inner adhesive, use a suitable hot melt tape as an alternative.

Tips for attaching the heat shrink tubing

Tip 1: Ideally, start the shrinking process in the middle area of the heatshrink tubing. Then gradually move to one end and then from the middle back to the opposite end. This prevents air from being trapped, which would cause bubbles formation.

Tip 2: The heat shrink tubing also shrinks in the longitudinal direction. This should be taken into account when cutting the part to be applied.

Tip 3: During the shrinking process using heat, always make sure that the workplace is well ventilated and use suitable safety equipment.

Hot melt adhesive solutions

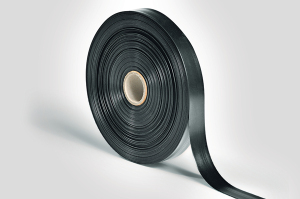

There are different hot melt adhesive products for specific applications. On the one hand, there are heat-shrinkable sleeves with inner adhesive, so-called dual-wall tubes. On the other hand, adhesive is also available separately as hot melt adhesive tape on rolls.

HMT200A, hot melt adhesive tape for heat shrink tubing and molded shapes: usually used for attaching joints and heat shrink tubes that have no adhesive. It guarantees adhesion, sealing and protection against moisture and dirt.

TSA-200 high temperature hot melt adhesive tape for low profile products: compliments -9 and -8 material (SCX15112 and SCX15111) whilst having good resistance to water ingress, flows when heated to provide a permanent environmental seal.

Tubing with inner adhesive: usually chosen for cables that are grounded or exposed to dirt and moisture. The adhesive helps the tube to have greater adhesion to the cable and ensures greater protection against environmental influences.

There are various types of heat shrinkable tubing with internal adhesive, each with different properties. The requirements vary depending on the area of application. Therefore, certain heat shrink tubes are better suited for certain industries than others.

Here are some product examples related to their primary field of application:

Automotive industry: Especially around aluminium-copper connections, the SA47-LA is the perfect choice. What makes it so special, especially for the automotive industry, you can read here in this blog article.

Rail industry: Some sectors, such as the rail industry, have special requirements for the fire behaviour of materials and components. With its excellent flame-retardant properties, the TA37 is the ideal choice here.

Shipbuilding: Salty air, permanent sunlight, harsh weather conditions, oils, mechanical stress: shrink tubing in shipbuilding has to withstand a lot. Solutions such as the MA40 or the HA40 are made for the demanding requirements on the high seas.

Electrical Installation: The practical HIS-A dispenser boxes are a popular “everyday solution” among electricians, because they always have the desired shrink tubing ready to hand. Whether for protection, insulation, moisture sealing or colour coding. Also popular is the MA47, a real all-rounder in terms of reliable electrical insulation.

In the video above, heat shrink experts Barry and Mark demonstrate how to make an environmental seal on a cable jacket using heat shrink shapes and adhesive tape. At first glance it may seem a bit complicated, but if you take a closer look you will see that everything is very simple, clear and secure.

#BR10 #4712