Formula Student Team Delft harnessed for success

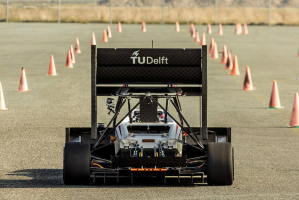

Formula Student is an annual construction challenge with a series of races around for budding engineers around the globe to compete in. On 3 June the team from the Delft University of Technology in the Netherlands unveiled its latest vehicle – the DUT16 – for the 2016 competition. HellermannTyton is proud to support this young team with parts and technology for their spectacular racing car.

When DUT16 pulls out of the pit lane at the Silverstone race track in Great Britain on 14 July 2016 for the first time, Team Manager Bas aan de Stegge will hold his breath until he hears a roar – not from the 80 kW electric motor, but from their 70-strong crew as Formula Student Team Delft driver Tim de Morée puts his foot down and blasts their exceptional vehicle onto the circuit.

When DUT16 pulls out of the pit lane at the Silverstone race track in Great Britain on 14 July 2016 for the first time, Team Manager Bas aan de Stegge will hold his breath until he hears a roar – not from the 80 kW electric motor, but from their 70-strong crew as Formula Student Team Delft driver Tim de Morée puts his foot down and blasts their exceptional vehicle onto the circuit.

Formula Student Team Delft was founded in 2000. The highly experienced team is known for its lightweight and agile cars and is currently ranked 3rd in the world listings. After Silverstone, DUT16 will also compete at the Hockenheim Ring in Germany from 9 August and the Circuit de Barcelona in the Spanish leg of the competition from 24 August 2016.

Formula Student explained

Strongly supported by the automotive industry, the competition provides students in over 500 teams from higher education colleges around the world with a unique opportunity to combine textbook theory with practical experience building and managing a single-seater racing car and team for real.

Strongly supported by the automotive industry, the competition provides students in over 500 teams from higher education colleges around the world with a unique opportunity to combine textbook theory with practical experience building and managing a single-seater racing car and team for real.

Since the Society of Automotive Engineers founded Formula SAE in the USA in 1981, the competition has grown to include annual races in Great Britain, Italy, Japan, Brazil, Germany and now Austria, the Czech Republic, Hungary and Spain.

The entrants are not just judged on the track performance of their vehicle for acceleration, endurance and efficiency in a series of races, but also in static disciplines ranging from their business plan, cost calculation, presentation and safety concept.

Phenomenal power to weight ratio

DUT16 is as strong as an ox and faster than a cheetah: at only 160 kg and with 80 kW (108 PS) available, this gigantic power to weight ratio means that the monocoque can accelerate from 0 to a 100 km/h in just 2.2 seconds – quicker off the mark than a Bugatti Veyron Super Sport, the world’s fastest production car!

DUT16 is as strong as an ox and faster than a cheetah: at only 160 kg and with 80 kW (108 PS) available, this gigantic power to weight ratio means that the monocoque can accelerate from 0 to a 100 km/h in just 2.2 seconds – quicker off the mark than a Bugatti Veyron Super Sport, the world’s fastest production car!

“That kind of acceleration produces forces up to 3 g and places tremendous strains on the driver, the carbon fibre hull, cable harness and electric system. After excellent first experiences with donated parts for last year’s DUT15 we turned to HellermannTyton again for sponsorship with cable management expertise in 2016”, says Team Manager Bas aan de Stegge.

“That kind of acceleration produces forces up to 3 g and places tremendous strains on the driver, the carbon fibre hull, cable harness and electric system. After excellent first experiences with donated parts for last year’s DUT15 we turned to HellermannTyton again for sponsorship with cable management expertise in 2016”, says Team Manager Bas aan de Stegge.

Cable management expertise

Weight is an extremely important component of DUT16’s performance. HellermannTyton products allow the Delft team to build a completely custom wiring harness for the car. This gives the construction team maximum design freedom and control of every single gram.

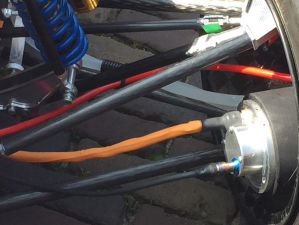

“The toughest challenges we faced while building a high performance race car are the safety and insulation of the High Voltage (HV) systems”, says Thomas van der Hout, Powertrain Chief for DUT16. “At full power over 120 amperes run through the HV wires! That can cause a lot of disruptive noise in the car’s sensor system”, he notes. “We use HellermannTyton HelaTape Shield 310 self-amalgamating tape and Helagaine HEGEMIP electromagnetic protection braided sleeving throughout to ensure that interference is kept to a minimum whilst ensuring that everyone in or around the car is properly protected against the high voltage.”

“The toughest challenges we faced while building a high performance race car are the safety and insulation of the High Voltage (HV) systems”, says Thomas van der Hout, Powertrain Chief for DUT16. “At full power over 120 amperes run through the HV wires! That can cause a lot of disruptive noise in the car’s sensor system”, he notes. “We use HellermannTyton HelaTape Shield 310 self-amalgamating tape and Helagaine HEGEMIP electromagnetic protection braided sleeving throughout to ensure that interference is kept to a minimum whilst ensuring that everyone in or around the car is properly protected against the high voltage.”

Building a cable harness from scratch requires a lot of patience. HellermannTyton has invested decades of experience from a variety of industrial scenarios to ensure that all its products can be applied simply and efficiently.

Building a cable harness from scratch requires a lot of patience. HellermannTyton has invested decades of experience from a variety of industrial scenarios to ensure that all its products can be applied simply and efficiently.

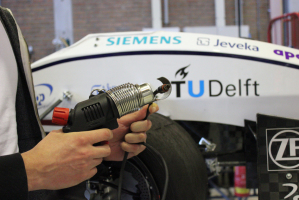

“HellermannTyton’s EVO7 cable tie application tool and the E4500 hot air gun allow us to work quickly and precisely”, enthuses DUT16’s Electronics Chief Bernard Bekker. “We can make the entire wiring for the vehicle in one day. That’s even more impressive when you know there are over 50 connectors in the car!”

“HellermannTyton’s EVO7 cable tie application tool and the E4500 hot air gun allow us to work quickly and precisely”, enthuses DUT16’s Electronics Chief Bernard Bekker. “We can make the entire wiring for the vehicle in one day. That’s even more impressive when you know there are over 50 connectors in the car!”

Reliable connections

Endurance contributes nearly a third of all the points the Formula Student teams can score in the challenge. The quality of the parts used contributes significantly to Delft team’s success. Cable fastening and insulation products from HellermannTyton have provided the team with excellent reliability under the toughest conditions – even when the car is put through a shower and run at top speed around a wet skid pad to see how it performs against extreme moisture ingress.

Every connection in the wiring system is critical to the team’s success. Damage to just one of them can result in us losing the race. Bumps and rapid steering movements demand the maximum from the components. Dust, water and high temperatures make the circumstances even more challenging.

TF31 heat shrink tubing combined with HMT200A hotmelt tape for extra protection against water and dust saves the team a lot of time during the production of the wiring. The high 3:1 shrink ratio makes it very easy to fit the sleeves to seal the wiring connectors for the on-board electronics.

“HellermannTyton MB2APT cable tie mounts with special acrylic-based adhesive allow us to quickly and securely install the wiring system to our carbon fibre chassis”, comments DUT16 Chief Engineer Tom Spoel. “We have used this technique for a couple of years in our team and know that it is the most convenient and reliable attachment of the cable to the chassis.”

“HellermannTyton MB2APT cable tie mounts with special acrylic-based adhesive allow us to quickly and securely install the wiring system to our carbon fibre chassis”, comments DUT16 Chief Engineer Tom Spoel. “We have used this technique for a couple of years in our team and know that it is the most convenient and reliable attachment of the cable to the chassis.”

#SponsoringTheFuture

Start your engines…

The team unveiled the DUT16 in Delft market square on 3 June 2016. Here you can watch a build-video showing how the race car was assembled.

The team unveiled the DUT16 in Delft market square on 3 June 2016. Here you can watch a build-video showing how the race car was assembled.

We will be avidly following the progress of Formula Student Team Delft throughout the summer. Best of luck!

You can subscribe to updates on the team’s Facebook page, Twitter, or via the official team page

#2188