RFID cable ties from HellermannTyton can simplify several of your industrial processes. But how exactly?…

RFID cable ties: Making product labelling more efficient and secure

Picture the scene: The labelling machine at an automotive supplier is printing and applying labels with product information to help monitor the maintenance of lambda sensors. One by one, boxes leave the production warehouse. But when they are opened at the car manufacturing plant, a nasty surprise awaits the fitter: the machine was not aligned properly. The barcodes are overhanging slightly. High temperatures in the warehouse have caused the protruding parts to ripple and stick together. The product information is no longer comprehensible. A solution must be found. In this article you will discover how RFID cable ties withstand harsh production conditions and how this makes your production more secure and more efficient.

“Conventional labels can peel off easily if the products are exposed to particularly harsh environments,” explains Marco Schaffer. He works as a Product Manager at HellermannTyton. Many of his customers are from the automotive industry and are addressing the subject of Industry 4.0 and the new digital opportunities. “One of our customers was looking for a solution for product labelling that can withstand high temperatures or contact with liquids. And above all, a solution that is forgery-proof.”

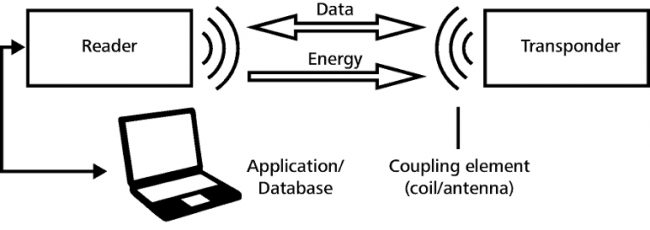

The solution to the problem came in the form of the RFID cable tie from HellermannTyton. The RFID technology (Radio Frequency Identification) transfers information wirelessly, by means of low and high-frequency radio waves, as well as UHF (ultra-high frequency). RFID cable ties from HellermannTyton are also fitted with a passive transponder and work without any additional power supply. Depending on the material – plastic or metal – they are suitable for areas in which they need to be particularly durable or resilient.

RFID cable ties: robust transponder for product labelling

“Our customer who prints onto the lambda sensors has until now only been recording the date, employee, shift and value of the lambda sensor using conventional labelling. Then the barcodes are applied by a machine and subsequently sent to the plant. Here the data is read and built into the vehicle with the sensor,” explains Marco Schaffer. “Using RFID cable ties saves the customer the stage of applying the barcodes on site.” In addition, new machines for labelling that meet the specific requirements of the customer will no longer be needed in future.

Because the RFID chip has a globally unique number other new processes are possible. This means the chip can be recorded in advance and managed using a conventional database or piece of software. A special programme is not required.

Product security and protection with RFID

“RFID cable ties save our customers a few tasks,” explains product manager Schaffer. “They are cable ties and product labels in one. They are also easy to attach and optimise security as a one-piece system. Once a cable tie has been cut it cannot be reused. This means that RFID cable ties guarantee the validity of the information stored on them. This also makes them suitable as a reliable RFID tag, for example for goods surveillance or for tool management. For large quantities of items, RFID cable ties can also be applied easily using the EVO7 application tool.”

More efficient production with RFID cable ties in Industry 4.0

RFID cable ties open up entirely new prospects and opportunities in digitised industrial applications.

- RFID cable ties can be used when other labelling methods are not suitable or do not reliably stay in place.

- RFID cable ties can be read in harsh environments – unlike barcode labels that often become illegible over time.

- RFID transponders in metal cable ties can withstand harsh production environments.

- They are durable and minimise the risk of having the wrong product information.

- As a storage medium and information carrier they can be used to identify parts, tools, their whereabouts, characteristics or even contents.

“For processes in which cable ties are used anyway, there is actually no longer any reason not to use RFID solutions,” says Product Manager Schaffer. “I see this possible application for RFID technology as a huge opportunity to simplify many processes in modern business significantly and make them more secure.”

#2849

Good products…