Heat-resistant cable protection: what other industries can learn from a furnace manufacturer

Picture a manufacturer of industrial furnaces. The new production facility is up and running, but the machines are not working as they should. Time and again there are unexpected problems and finally, production has to be stopped. Apparently, high temperatures and electromagnetic radiation (EMC) from the electrical cables are causing interference between the machines. Read this article to find out why you should include a professional cable protection system in your parts list.

“The furnace manufacturing case shows how important it is to plan the cable protection system while plant machinery is being constructed,” explains Anja-Karolin Schulze, Product Manager for Protective Cable Systems at HellermannTyton in Germany. The manufacturer in question had designed the plant without defining any cable protection.

“The furnace manufacturing case shows how important it is to plan the cable protection system while plant machinery is being constructed,” explains Anja-Karolin Schulze, Product Manager for Protective Cable Systems at HellermannTyton in Germany. The manufacturer in question had designed the plant without defining any cable protection.

The machine cables were neither completely heat-resistant, nor did they provide enough EMC protection. The unprotected cables represented an engineering weak point. “In this case, our customer required a fast solution combining EMC metal protective conduits and threaded fittings suitable for high temperatures.” (See: Page 95, HelaGuard Product Catalogue)

Whether a specialist scenario or a typical incident – such as a forklift running over wiring repeatedly – cable protection is often left till last, or not properly addressed at all when industrial installations are being designed. That can lead to unnecessary additional costs. In the worst case, leads and cables hang or lie around without protection in the machine area, making them extremely prone to damage. “Or the machinery does not run as efficiently as it could,” says Ms. Schulze. Her conclusion: “Once you have had a bad experience, you will never plan and construct a system again without a concept in place for proper cable protection.”

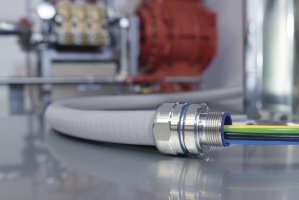

Without the correct fitting, the best protective conduit will have weak points.

“It is ideal to think of cable protection during the construction stage and to rely on system solutions such as HelaGuard,” advises Ms. Schulze. Every protective cable hose has unique features, depending on its area of application. Only with the right fitting with an effective seal for each conduit can you ensure that the protective system will perform as required.

Product expert Anja-Karolin Schulze: “It is not only important to protect the cables with conduits or tubing, but to also protect each end with suitable fittings. Otherwise the cable protection system will be vulnerable. If conduits are not properly sealed with the correct fitting, cables are open to unwanted and potentially dangerous mechanical or chemical influences or contact with water.”

Cable protection systems help prevent damage

With the HelaGuard product range, HellermannTyton offers the ideal system solution for any application. This includes protective conduits, tubing and sleeves, screw fittings and accessories.

With the HelaGuard product range, HellermannTyton offers the ideal system solution for any application. This includes protective conduits, tubing and sleeves, screw fittings and accessories.

Especially in the field of plastic tubing, HelaGuard leads the competition. “Our patented plastic fittings include a safety locking mechanism. They can be mounted quickly, yet prevented from being easily opened or loosened without inserting a screwdriver.”

This is ideal for companies who work with high amounts of tension on their cables or deal with vibrations or even wanton tampering. “In robotics, for example, the system must provide safety even under constant motion,” explains Ms. Schulze.

HelaGuard – shock-resistant, heat-resistant and liquid-tight systems

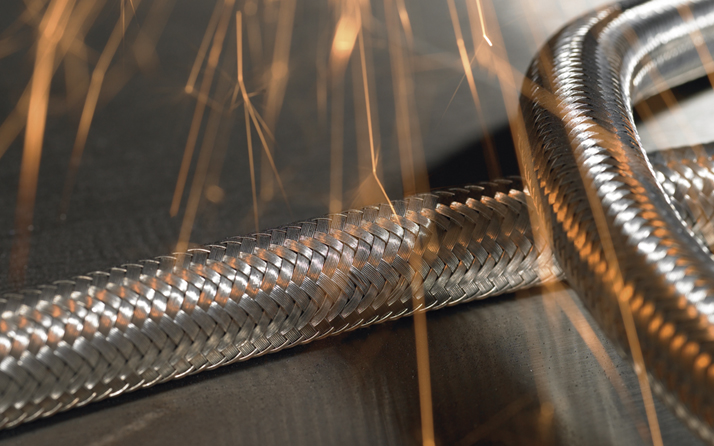

When working with temperatures in the range of -100 to +300 degrees, heat-resistant conduits and screw fittings should be used. HellermannTyton offers the HelaGuard SCSB system – a combination of galvanised steel tubing and galvanised steel mesh. It is resistant to extreme temperatures, high impact and mitigates the effects of electromagnetic fields on cables, and vice versa. HellermannTyton also offers conduits made of stainless steel and galvanised copper as solutions with the corresponding screw connections for an even higher degree of EMC protection.

For additional protection against liquids, the galvanised steel conduit is also available with a PVC covering. It combines the advantages of steel and plastic and offers many advantages, especially when used outdoors: “The system runs under the name LTSH and is resistant against grease, oil, acid and petrol. It is widely used by our customers who have offshore applications,” explains Ms. Schulze.

Finding the right cable system

The HelaGuard protection system is categorised by features that will help you select the right system. Apart from IP classification, the system comprises conduits, tubing and fittings grouped according to compression strength, pull-off force and minimal bending radius. A useful guide for selecting the right cabling protection system can be found on page 4 of the HelaGuard catalogue.

Do you have any questions or would you like a consultation about cable protection for your machines or plants? Contact us today!

#1686