Innovation often comes from thinking about an existing product in new ways. Recently at HellermannTyton…

Detectable Metal Content Cable Accessories for the Food and Beverage Industry

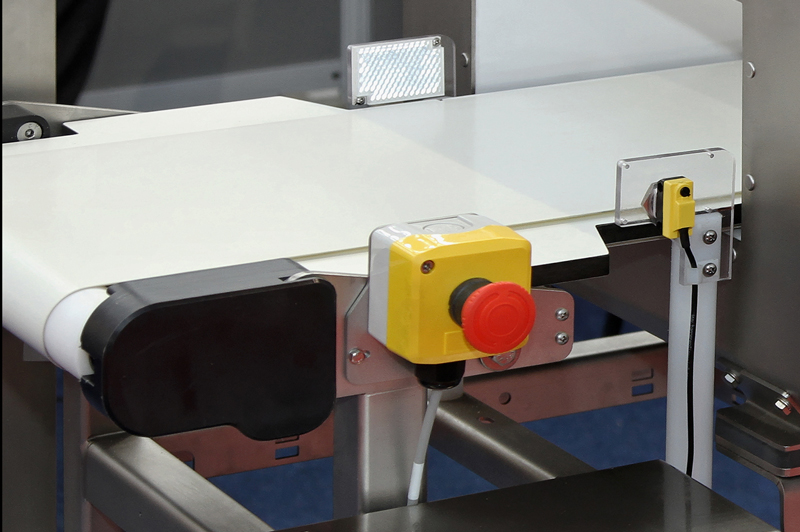

Your food and beverage production facility is state of the art. You comply with all relevant regulatory standards. Yet one day, during routine maintenance, a plastic cable tie is accidentally cut and lands somewhere on the processing line, the batch is contaminated. Suddenly your reputation for safety and hygiene is on the line. How can you avert a minor drama turning into a major crisis?

HellermannTyton understands the challenges you face

Undetected contamination of a production batch with a foreign body is a horror scenario for any food or beverage manufacturer, regardless of whether it’s in the baked goods, processed meat, dairy products or health and pharmaceutical products sector.

Despite best efforts, however, accidents do happen. For this reason, manufacturers implement the Hazard Analysis and Critical Control Point (HACCP) approach. Here they employ visual detection methods (such as coloured components), and x-ray and metal detection devices to control and assure production quality and the integrity of batches and product.

The HACCP principles are included in the international standard ISO 22000 FSMS 2005. For more information regarding the HACCP principles, click here.

Highly detectable cable solutions contribute to quality control and assurance

HellermannTyton understands the needs of food and beverage processors. Our experience in the sector goes back further than any of our competitors. After all, we were the first to bring a detectable plastic cable tie onto the market.

HellermannTyton understands the needs of food and beverage processors. Our experience in the sector goes back further than any of our competitors. After all, we were the first to bring a detectable plastic cable tie onto the market.

Today our metal content cable solutions provide one of the highest levels of detectability – ranging from a ferrous sphere setting of 1.0 mm to 3.4 mm using industry-accepted measurement techniques. Even distribution of metal content throughout our products means that small fragments, like the one in the worst-case scenario outlined above, can be easily detected.

Ensure the correct % water dosing

Correct water content is crucial for the smooth installation of MCT cable ties. In contrast to standard plastic cable ties, the metal content in specially detectable MCT ties makes them more susceptible to becoming brittle when they dry out. The correct moisture level ensures that the moving parts remain supple and flexible at installation. We guarantee that the material absorbs the correct amount of moisture when packaged. It is therefore extremely important to ensure that MCT cable tie bags remain sealed when stored, especially in dry and cold environments.

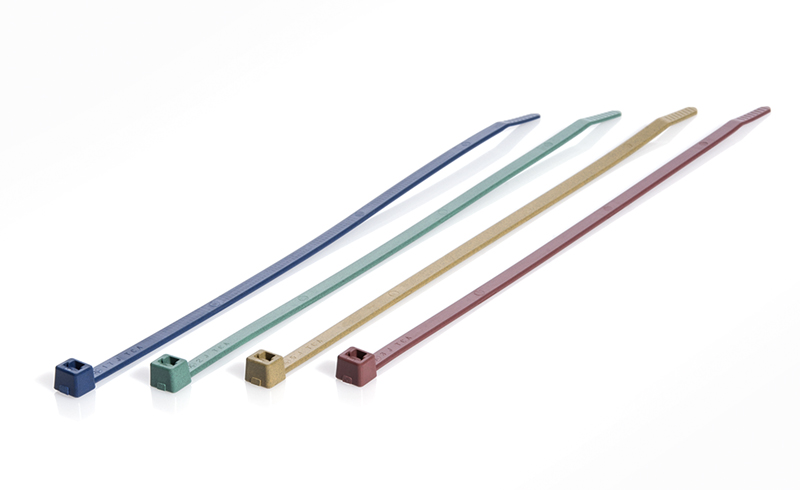

Metal content portfolio: ties and mounts, spiral binding, cable covering and fittings

Our metal content portfolio for the food and beverage sector encompasses metal content ties and mounts, metal content spiral binding, cable covering and fittings, stainless steel cable ties and mounts, and application tools for optimal fitting.

All products are manufactured from high-grade materials and most have been designed to specifically conform to requirements of the US Food and Drug Administration (FDA), EC No. 1935/2004, as well as to various national standards. Our detectable products can therefore contribute significantly to process quality.

Indeed, the MCTS cable tie in our range of metal content ties leads the market in terms of detectability. Fragments of this metal content cable tie are detectable down to 1.0 mm.

All the ties in our MCTS series are highly resistant to corrosion, making them ideal for salty environments and cleanrooms. Furthermore, MCTS is suitable for operating temperatures from -40 °C to +85 °C.

But HellermannTyton’s range of cable accessories for food and beverage producers does not end there. For instance, corrosion-resistant stainless steel MBT cable ties are the product of choice for coping with high mechanical loads and temperatures common in food processing. Further information on MBT cable ties can be found here.

To discover whether detectable cable ties and fixing elements made from plastic with metal content, polypropylene, E/TFE or stainless steel are most suitable for your applications, please consult the technical tables in our Detectable Products for Food and Beverage Production brochure.

You will also find an overview of our easy-to-clean and chemical resistant cable protection conduits, heat shrinkable tubing and marker plates in the brochure.

Are you a food or beverage manufacturer and have a need that is not currently met by the market, or would you like to share your experiences regarding detectable cable management solutions? We welcome your comment.

#1325

hello there,

may I know where exactly or what is the main usage of these product?

the detectable ties and mounts?

Hi Betty Jane Lausan, watch this video: https://youtu.be/B0gnmnlWxqw