Picture the scene: The labelling machine at an automotive supplier is printing and applying labels…

Industry 4.0: How RFID cable ties simplify traceability in harsh production conditions

Between dirty shrink discs, hydraulic oil and muck: the workplaces of industrial mechanics in the hydraulic service are not exactly the cleanest. Anyone who services hydraulic components and systems can find that important product labels and informative barcodes are no longer legible due to the dirt. The air pressure and last service date may no longer be recognisable.

In this article, find out how cable ties with RFID technology simplify the traceability of products in harsh environments.

“The requirements of the hydraulic servicing described here were the starting signal for the product development of our RFID cable ties,” recalls Marco Schaffer, Project Manager at HellermannTyton. “Another means of labelling products was needed. Identification needed to withstand high temperatures and temperature fluctuations and be resistant to fluids. It also had to be easy to install while helping our customers with the organisation of cables.”

As a solution, HellermannTyton developed cable ties with an integrated RFID (Radio Frequency Identification) transponder for the customer. The RFID cable ties are not just used in hydraulic servicing now. “Our customers can choose the appropriate cable tie material properties according to the production environment. This brings many advantages to many industries.

For example, customers from the food industry use RFID cable ties which have metal incorporated. This makes them discernible for metal detectors and X-ray equipment – so food manufacturers can ensure that no parts of cable ties accidentally get into the end products.

Other companies need RFID cable ties made entirely of metal, so that the transponders stay in place despite extreme conditions.”

Simplified traceability with RFID systems in production

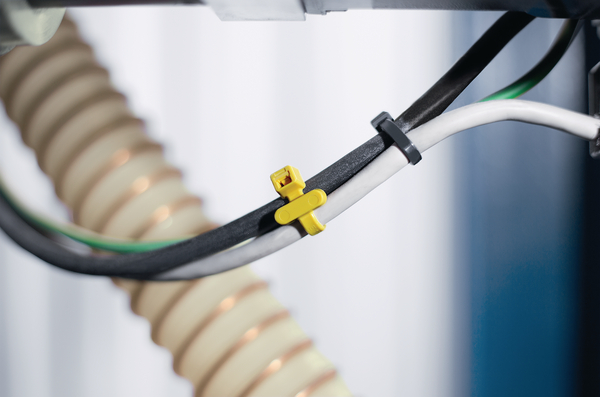

RFID system solutions by HellermannTyton consist of a cable tie with an integrated RFID transponder and a corresponding reader as an interface to a database.

See a video describing the entire process, click here – Industry 4.0: innovative solutions for RFID cable ties (EN).

RFID technology identifies and processes information with the aid of low and high frequency radio waves with no additional power supply. The cable tie material determines which production conditions the RFID cable tie is suitable for: as a means of labelling, it is resistant to fluids and even varnish, as RFID works without contact. This means the data can be read reliably at any time.

Time and cost savings with RFID systems

“RFID cable ties eliminate tasks and greatly reduce costs for our customers: for example, for expensive labelling machines that have to be adapted to the customer’s individual specialist requirements and production conditions. In addition, they can completely outsource the expensive labelling process and the RFID cable tie provides a two-in-one solution: they label the products and bundle them with the aid of the cable tie. They are especially useful when there is already minimal space for a label,” explains Marco Schaffer. A smooth production process is guaranteed – cables do not sag anywhere or present a safety risk for employees.

Other industries, such as the automotive sector, also use RFID technology for the traceability of parts. Clear product labelling using cable ties ensures that the source of errors can be clearly identified in the event of a defect in the end product. Every stage of production is completely documented on the RFID chip: components, people, whereabouts, properties, date and contents. In the event of damage, targeted recalls can be initiated in this way. That’s why more and more suppliers are manufacturing their cable harnesses with RFID cable ties.

Traceability in every environment: read data reliably

The fact that every component is traceable also benefits goods inward processes. Costs are more transparent, processes along the value chain can be optimised. Counterfeit products are easier to identify. The use of RFID cable ties can even make them completely impossible.

Once a cable tie has been cut, it cannot be reused – as each RFID chip has a globally unique ID number. This means that RFID cable ties guarantee the validity of the information stored on them.

What processes could you simplify with RFID technology?

Traceability and RFID technology are emergent topics in the concept of Industry 4.0. “In combination with our high-tech cable ties, there is a lot of potential for new ideas based on individual customer needs. The technologies are available. Now is the time to develop visions for their application, as traceability concepts based on the newly developed RFID cable ties offer huge advantages in terms of cost and time savings for a wide variety of industries”, says Marco Schaffer.

#3811