A quick look under any desk, in any server cabinet or electrical enclosure will show…

Simple, stable and safe electrical installations with gel cable joints

Whether unplanned or part of scheduled maintenance, electricians need to connect low-voltage power supply cables on a regular basis. Cast resin technology or heat shrinkable sleeves are frequently used to safely protect cable connections. However, the reliability of the end result largely depends on the way the materials are handled during their tricky installation. Modern gel cable joints are a time-saving and reliable alternative.

Gel joints: the new trend in cable connection protection

Gel cable joints have become increasingly popular in electrical installations. They can be used as straight through or branch joints for repairing defective cables. They are available in different sizes covering all common conductor cross-sections.

Gel cable joints have become increasingly popular in electrical installations. They can be used as straight through or branch joints for repairing defective cables. They are available in different sizes covering all common conductor cross-sections.

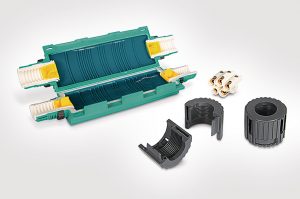

The joint shells are made of UV- and impact-resistant polypropylene. The prefilled gel is non-toxic and highly insulating >20kV/mm and guarantees watertight protection of the cable connection. It can also be stored indefinitely. For more information click here: www.hellermanntyton.com > Competences > Gel filled cable joints

Quick, simple and effective

The main advantages of gel cable joints are obvious when you work with them for the first time. In contrast to heatshrink tubing or cast resin joints, where the electrician must plan time for additional installation steps, using a gel sleeve is quicker and less labour-intensive.

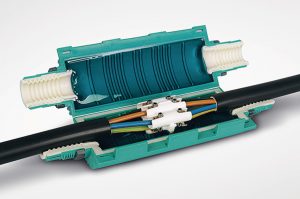

After the cable ends have been connected using an appropriate terminal block the prepared connection is simply pushed into the gel and the shell closed until it snaps into place. No special tools are required and the power can be switched on immediately.

See for yourself, as our electrician demonstrates the installation of the Reliseal gel joint:

Service technicians are embracing gel joints quickly because they are ready to use out-of-the-box. No mixing and filling is required, the mixture doesn’t get warm as it cures and there is no time delay involved until the joint is ready to use. Gel joints can be put into operation immediately.

Built for different needs

HellermannTyton RELICON gel cable joint range includes Relifix, Relilight and Reliseal. They share many commonalities, even though they are designed for different application ranges and cable diameters, for example, single-conductor cables 1 x 10 mm² to 1 x 50 mm² and 5-strand cables from 1.5 to 16 mm² and 6 to 25 mm².

Relifix gel cable joints are suitable for the universal connection of cables and leads with sheaths made from PVC, XLPE, PE and EPR. The polypropylene shell is impact-resistant and flame-retardant and suitable for underground and overground cable connections and repairs in low-voltage power supplies in and around buildings.

Check out this step-by-step Relifix installation video:

HellermannTyton also offers two further RELICON gel joints with IP68 protection classification.

Compact Relilight gel cable joints are intended for the small wire cross-sections frequently encountered in light installations, especially LED lighting systems. They are perfect for all applications requiring a tight seal (protection class IP68 1.3 metres) with mechanical protection, for example outdoors, around sanitary facilities or swimming pools. Relilight can be used from -30°C to +130°C.

Compact Relilight gel cable joints are intended for the small wire cross-sections frequently encountered in light installations, especially LED lighting systems. They are perfect for all applications requiring a tight seal (protection class IP68 1.3 metres) with mechanical protection, for example outdoors, around sanitary facilities or swimming pools. Relilight can be used from -30°C to +130°C.

A short video showing how to work with Relilight is available here:

Reliseal gel cable joints are extremely robust and fulfil the highest electrical engineering requirements. They provide ultimate protection for electrical connections in unfavourable conditions, especially in the ground and under water (protection class IP68, 10 metres). The patented screw system also ensures unparalleled strain relief.

If necessary, the screw system can be reopened later. The gel used in Relifix and Relilight is very flexible. This ensures access to the cable connection at any time. Voltage measurements can be taken at any time and the puncture channels reseal themselves completely afterwards.

The bottom line: gel joints provide mechanical protection, insulation and a seal in a single work step. Installers save time require no special tools for installation and it is simple to open the connection later if needed. It doesn’t get better than that, where repairs are critical and time is money!

Post us a comment below and share your experience using gel cable joints!

#2664

Dear Sirs,

For a landscape lighting project in Qatar, to install app 500 nos of 12W – 24VDC – RGB uplights, I wish to use your relevant product, suitable for connecting the lights to the main power , 5core x 2.5mm, multi strand flexible cables.

Please provide me with the price of your proposed and suitable gel type straight joint, inclusive of the courier freight to Doha, in the sate of Qatar.

Payment can be carried out via TT directly to your account.

Expecting your prompt response and action,

Sincerely

For INELT Co.

Michael Charalambous

General Manager

Dear Michael, we will forward your request. Best wishes, Nico