Cable splices and ring connectors are a common feature of electrical applications. But unreliable sealing…

Good, better, SA47-LA: How a shrink tubing sets new standards in terms of tightness

Length, material, colour, shrink ratio: Depending on the application, the requirements for heat-shrink tubing can vary considerably. That’s why the range of products is so large. If, for example, special protection against moisture and other environmental influences is required, customers prefer shrink tubing lined with adhesive. SA47-LA is one of these ‘dual wall’ products. However, this is no ordinary tubing. Especially where aluminium-copper connections need to be sealed it is the market leader. Read here what makes SA47-LA so special and in for which applications it is ideal.

SA47-LA heat shrink tubing with inner adhesive: features and benefits at a glance

SA47-LA is a semi-rigid, standard wall heat-shrink tube with an adhesive lining – “LA” stands for less adhesive. This is ideal for insulating copper-aluminium connections and is used, for example, for sealing cable shoes, welded connections and splices.

Particularly popular in the automotive industry, SA47-LA is also used in many other areas,including white goods,for example, in the manufacture of refrigerators.

What distinguishes SA47-LA from its competitors is its special thermoplastic inner adhesive. This is discussed in more detail below.

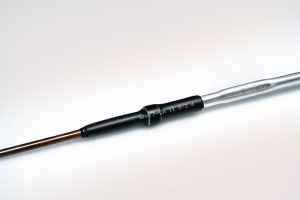

Thanks to the use of a black-coloured adhesive and a transparent outer sleeve, the result after shrinking can be checked visually. In other words: the optimal spreading of the adhesive and the control of trapped air bubbles or soiling.

The main features in a nutshell:

- Special EVA-based black adhesive (see below for details)

- Excellent protection against moisture and corrosion

- Ideal choice for copper-aluminium connections

- Transparent shrink tubing for final visual inspection

- Resistant to typical automotive oils and fluids

- High shrink ratio of 4:1

Here you will find an overview of all variants of the SA47-LA.

Designed to prevent electrochemical corrosion

One of the three largest German automobile manufacturers had the following problem: Electrochemical reactions repeatedly occurred with the metal connections (aluminium-copper) produced by friction welding. The result: corrosion, which in the worst case can lead to system failures and thus to expensive recalls. The company therefore commissioned various manufacturers, including HellermannTyton, to find solutions to this problem.

Various products were tested. However, most of them failed at the beginning. Only one product solution successfully passed all tests from start to finish and even exceeded the customer’s expectations: SA47-LA shrink tubing. The secret of its success lies mainly inside the shrink tubing.

Premium class inner adhesive: the heart of the SA47-LA

While most heat shrink tubing is equipped with a polyamide-based adhesive, the SA47-LA features a black EVA-based adhesive (ethylene vinyl acetate). This is characterised by a very low viscosity. In other words, it is extremely fluid. As a result, it flows into even the smallest pores and cracks when heated. Should air be trapped, this is visible afterwards thanks to the transparent tubing.

Rock-solid yet flexible: The unique inner adhesive of the SA47-LA is highly impermeable. However, this adhesive has another major advantage – it remains flexible after application. This means that SA47-LA can easily withstand even strong vibrations. Many other adhesives, in contrast, would quickly delaminate under movement.

According to several well-known vehicle manufacturers, the above-average quality of the adhesive in combination with the resistant, transparent material makes SA47-LA the “best shrink tubing on the market” for their needs.

The SA47-LA in test: optimal results at 3 bar and more

The so-called bubble test is a method of testing the tightness of a heat-shrinkable tubing. In order to test the quality of the SA47-LA, it was shrunk onto a pre-assembled cable fitted with a cable shoe. The appliance was then immersed in a water bath under positive pressure.

The aim of such a test is to increase the overpressure until the test gas has found its way through the shrink tubing – recognizable by small bubbles rising in the water bath. Result: Depending on the cable shoe geometry, the SA47-LA withstood a pressure of up to 5 bar.

In comparison: The factory standard of a major German automobile manufacturer generally stipulates that products for the highest tightness class must withstand a pressure of 1.5 bar. The SA47-LA thus exceeds these requirements by more than a double.

Tailored to individual requirements

The SA47-LA is available in a standard length of 1.2 metres. Depending on the order volume, HellermannTyton can also supply this heat shrink tubing in an individual length requested by the customer.

Please contact your HellermannTyton sales representative if you are interested or have any questions about the “cut-off service” or use this contact form for your enquiry.

The right shrink tubing for your application

Whether thin-, standard- or thick-walled, coloured or transparent, UV-resistant or flame-retardant: In addition to the premium shrink tubing SA47-LA, HellermannTyton offers many other solutions for the most diverse requirements. Find out more about heat shrink tubing from HellermannTyton here.

#4229