Cable splices and ring connectors are a common feature of electrical applications. But unreliable sealing…

Electro vehicles – Orange heat shrink tubing: A sign of the times

Future mobility solutions involving electro motors are being talked about everywhere.*

Increasing demand for a particular colour variant of a HellermannTyton product gives us an indication that the trend towards hybrid and electro vehicles (EVs) is now rapidly picking up momentum.

Find out why orange is a signal colour for HellermannTyton.

Electro vehicles – Caution high voltage!

Electro vehicles run off direct battery currents up to 400 V and alternating currents over 600 V or even up to 1000 V in the motor power system.

Electro vehicles run off direct battery currents up to 400 V and alternating currents over 600 V or even up to 1000 V in the motor power system.

High voltage cable insulation and connecting components in hybrid and electro vehicles are coloured orange.

Orange clearly signals to mechanics and rescue personnel the sources of high voltage danger in these new vehicles.

Due to the higher temperatures and the immediate risk of injury, all materials used in high voltage systems must meet the requirements of special standards.

HellermannTyton’s TF21 cross-linked polyolefin (PO-X) heat shrinkable tubing is particularly suited to use in EVs, for more information click here: TF21 Orange. Recently, orders for the orange colour variant have been rising markedly.

The explanation for this growing demand lies in the fact that TF21 heat shrink tubing offers an optimal combination of electrical and mechanical protection. It shrinks quickly (2:1 ratio) at relatively low temperatures, is flame-retardant (UL 224), printable and highly resistant to chemicals – and we supply it in orange.

Channelling innovative sparks for the automotive industry

Because tomorrows’ cars are being designed today, we are applying our longstanding experience in the production of custom series components for the automotive industry to develop ingenious solutions to the new challenges posed by electro vehicle manufacturing.

Weight reduction makes a fundamental contribution to the energy efficiency of all modern vehicles. Our product developers work closely with customers to develop suitable alternative parts from plastics.

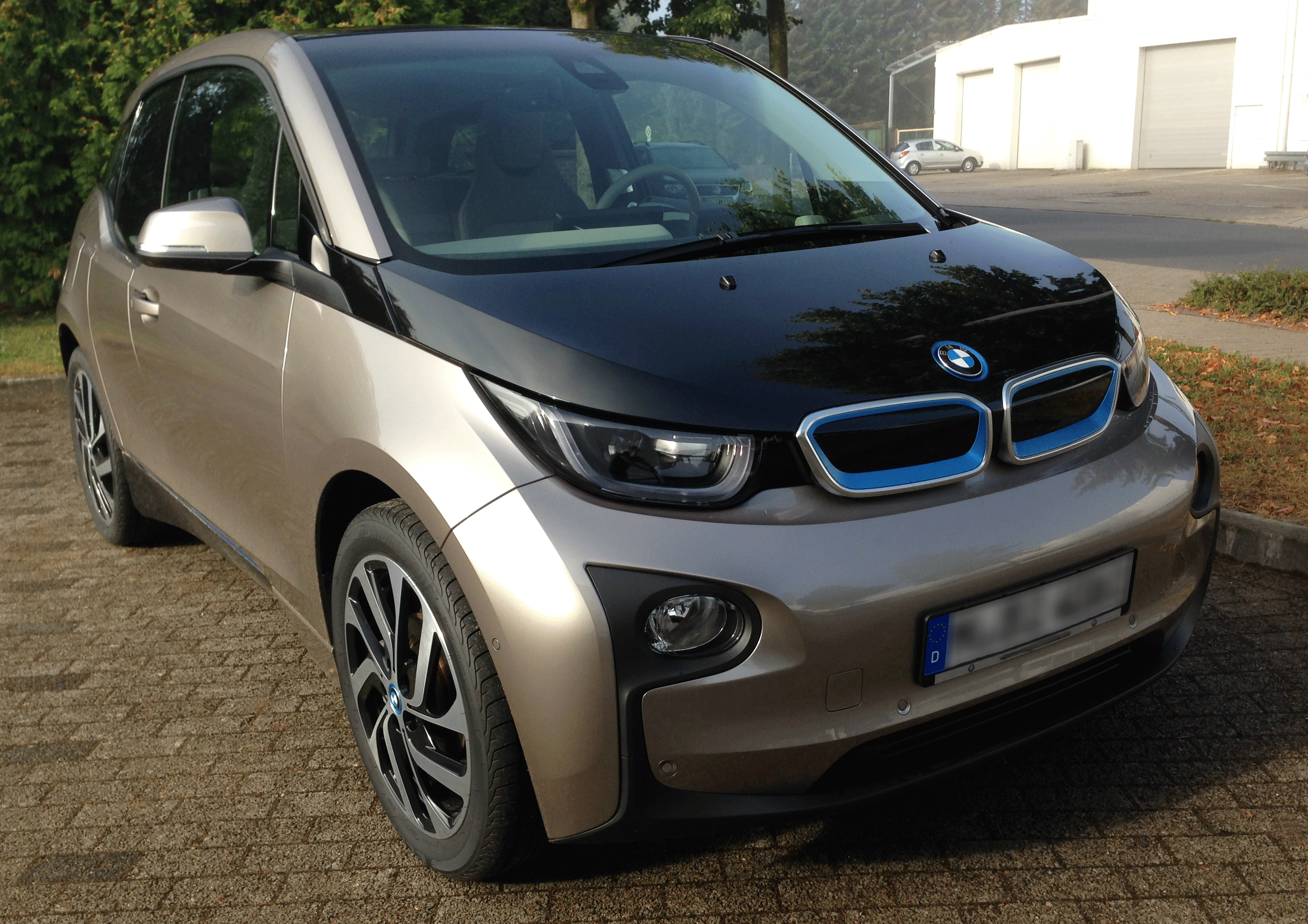

Besides standard parts, such as TF21 orange tubing, HellermannTyton also develops customer-specific components such as clips, ducts and mounting brackets for brands such as BMW and Mercedes-Benz.

From the charging socket throughout the entire high voltage cable harness, our innovations can be found, for example, in the BMW “i” range of plug-in electric cars and in vehicles built on the Mercedes E-CELL platform.

You can discover more about HellermannTyton supports OEM customers and level I and II suppliers with their component development in our Automotive Competence Brochure.

Click here for: Calculator tool for Heat Shrink Tubing and the Wall thickness calculator

* Search terms Future+mobility+solutions+electro+motors

Update 2016-01-05:

Link Article of “Electric Mobility” click here (www.vda.de/ PDF)

“The German automotive industry is strongly committed to pressing ahead with the development of electric mobility because climate protection, a growing scarcity of fossil fuels and an increased need for mobility due to rising population figures require new solutions and alternative propulsion systems.”

Update 2018-04-24

Fraunhofer Institute for Systems and Innovation Research ISI “Electric mobility in all its facets” Press Release 2015-02-25 Continue reading

#1137